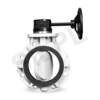

PVDF has outstanding barrier properties which allows a better protection of the environment. The construction of chemical process equipment makes use of a multitude of materials to cope with specific corrosion problems. PVDF has the advantage of absolute suppression of corrosion, even under varying process conditions, when compared to other materials.TECHNICAL INFORMATIONWhen compared with non-fluorinated thermoplastics, PVDF gives maximum reliance in chemical resistance, such as resistance to strong oxidising agents and concentrated mineral acids.

| Operating Temperature |

OperatingPressureforthefollowingPressureRatings |

| 150 psi / 10 bar |

232 psi / 16 bar |

| °F |

°C |

psi |

bar |

psi |

bar |

| -40 |

-40 |

150 |

10 |

232 |

16 |

| 68 |

20 |

150 |

10 |

232 |

16 |

| 104 |

40 |

117 |

8.1 |

190 |

13.1 |

| 140 |

60 |

96 |

6.6 |

152 |

10.5 |

| 176 |

80 |

75 |

5.2 |

117 |

8.1 |

| 212 |

100 |

58 |

4 |

90 |

6.2 |

| 248 |

120 |

42 |

2.9 |

67 |

4.6 |

| 284 |

140 |

27 |

1.9 |

13 |

3 |

Support Distances for PVDF pipes

| 0C |

20 |

40 |

60 |

80 |

100 |

120 |

140 |

| Spacing (m) |

1.524 |

1.524 |

1.27 |

1.016 |

1.016 |

1.016 |

1.016 |

Above table is valid for Density of fluid at 1000 kg/m3. It will increase based on correction factor below for higher density:

| Density of fluid kg/m3 |

1250 |

1500 |

2000 |

2500 |

2700 |

| Correction Factor |

0.94 |

0.83 |

0.77 |

0.7 |

0.57 |