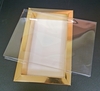

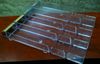

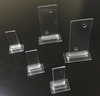

Cosmetics Blister in Ajman

Price On Request

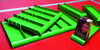

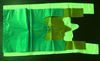

Vaccum Forming is a simplified version of thermoforming, where a sheet of plastic is heated to a forming temperature, stretched onto a single-surface mold, and forced against the mold by a vacuum. This process can be used to form plastic into permanent objects such as turnpike signs and protective covers. Normally draft angles are present in the design of the mold to ease removal of the formed plastic part from the mold. Relatively deep parts can be formed if the formable sheet is mechanically or pneumatically stretched prior to bringing it into contact with the mold surface and applying the vacuum.

Suitable materials for use in vacuum forming are conventionally thermoplastics. The most common and easiest to use thermoplastic is high impact polystyrene sheeting (HIPS). This is molded around a wood, structural foam or cast or machined aluminium mold, and can form to almost any shape. This high impact material is hygienic and capable of retaining heat and its shape when warm water is applied and is commonly used to package taste and odor sensitive products.

| Place of Origin | Not Given |

| Minimum Order Quantity | Not Given |

| Supply Ability | Not Given |

| Packaging Details | Not Given |

| Delivery Details | Not Given |